Comparing Rear Loader and Side Loader Municipal Sanitation Vehicles for Urban Waste Collection

Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

Recent studies show rear loader municipal sanitation vehicles work better than side loaders in cities. The table below shows important differences:

Aspect | Rear Loader Strengths |

|---|---|

Efficiency | Rear loaders pack trash tightly. They need fewer trips. They use machines to load trash. |

Cost | They cost less for workers. They are easy to fix. |

Crew Requirements | They need fewer workers. Their design is comfortable for crews. |

Maneuverability | They have short wheelbases. They can turn in small spaces. |

Safety | Workers stay away from traffic. They have good safety features. |

Environmental Impact | They make less pollution. Some use hybrid or electric power. |

Brands like CJQC help cities manage waste. They make new sanitation solutions for these needs.

Key Takeaways

Rear loader trucks can carry big trash items. They work best where there is mixed or large waste. These trucks need more workers and take more time.

Side loader trucks have arms that pick up bins fast. They do this safely and need fewer workers. This makes them cheaper for busy city streets.

New technology like hybrid engines helps cities save fuel. Route optimization and smart water systems also help cut pollution and costs.

Side loaders are safer because workers stay inside the cab. This lowers injuries compared to rear loaders, which need manual loading.

Cities should pick trucks based on their trash types. They should also think about street layouts, worker needs, and budgets. This helps make waste collection better and keeps the environment safe.

Vehicle Types Compared

Rear Loader Overview

Rear loader garbage trucks help cities collect trash. They work best where there is lots of garbage. These trucks are used in busy places and old neighborhoods. They can pick up big items and loose bags. Rear loaders handle dumpsters and need to be flexible.

Rear loaders have strong compaction systems. They pack trash tightly so fewer trips are needed. This saves time and fuel for the city. They can pick up furniture and appliances. Their design keeps loads low and stable. Rear loaders work well on steep hills. Cities use them for routes with lots of trash at each stop.

Tip: Rear loaders work great for bulk waste and renovation debris.

Side Loader Overview

Side loader garbage trucks are popular in crowded cities. Their design lets them collect trash from one side of the street. Operators use automated arms to lift bins. They do not need to leave the cab. This makes the job safer and helps prevent injuries.

Side loaders have many benefits for cities. They move easily through narrow streets and alleys. This makes them good for busy neighborhoods. Their small size and single-side pickup help traffic flow. New models use GPS and telematics to plan routes. This saves fuel and lowers emissions. The automated system makes trash collection faster.

Feature | Rear Loader | Side Loader |

|---|---|---|

Garbage Handling | Bulky, mixed, loose | Standardized bins |

Crew Size | Larger | Smaller (often 1) |

Efficiency | High compaction | Fast, automated |

Maneuverability | Good on hills | Best in tight spaces |

Compressed garbage trucks can carry more trash and need fewer trips. Both rear and side loaders help cities stay clean and safe.

Municipal Sanitation Vehicle Technology

Garbage Compressor Truck Features

Modern garbage compressor trucks are important for city waste systems. These trucks use hydraulic compaction systems to press trash down. This lets them hold more garbage and take fewer trips. Operators use easy controls to run the compactor and the truck. This helps them work faster and have less downtime. The trucks have big storage spaces for lots of trash. This is good for busy city routes.

Many trucks now have new technology. Telematics systems give real-time GPS tracking and remote checks. This helps plan better routes and fix trucks on time. Automated lifters use robotic arms to empty bins fast. This makes the job easier and quicker for workers. On-board scales weigh the trash for billing and planning. RFID technology tracks bins and helps keep records. Emission control systems lower pollution and help the environment. Safety features like backup cameras, warning lights, and emergency stops keep people safe.

Feature | Description | Efficiency Benefit |

|---|---|---|

Hydraulic Compaction System | Presses trash to fit more and take fewer trips | Saves time and fuel, helps trucks work better |

Spacious Storage Compartments | Holds lots of pressed trash | Covers more area and needs fewer pickups |

User-Friendly Controls | Makes running the truck and compactor simple | Less downtime and more work done |

Advanced Technologies | Has telematics, lifters, scales, RFID, and emission controls | Makes routes better, safer, and cleaner |

Automation and Hybrid Systems

Automation and hybrid systems have changed city garbage trucks. Automated side loaders use hydraulic pumps to lift and empty bins fast. This saves time and fuel. Sensors with IoT devices check how full bins are and how trucks are working. They send this data to the cloud to help plan routes. Cities like Glendale and Los Angeles use telematics and apps to track trucks. They check where trucks are, how engines run, and how drivers act. This makes routes better and service faster.

Hybrid engines use both diesel and electric power. They save energy by using brakes and sometimes solar panels. These systems use less fuel and make less pollution. Studies show hybrid trucks can cut CO2 by almost 30%. They also lower costs by about the same amount. Route software helps trucks drive the best way. This saves fuel and keeps traffic moving. Automation and smart planning cut costs and pollution. This helps cities manage waste better.

Note: Automation and hybrid tech in garbage trucks help cities be greener and give better service.

Collection Efficiency

Route Optimization

Cities want to pick up garbage fast and spend less money. Route optimization software helps both rear loader and side loader trucks do better. This software uses data to find the best way for each truck to go. It checks how many stops a truck can make. It matches the right truck to the right route. Automated side loaders can stop more times in one day than rear loaders. The table below shows how many stops each truck can make in 8 or 10 hours:

Vehicle Type | Average Stops per 8-Hour Route | Average Stops per 10-Hour Route |

|---|---|---|

Automated Side Loader | 800 – 1,000 | 1,000 – 1,200 |

Semi-automated Rear Loader | 700 – 900 | 800 – 1,000 |

Route optimization software helps cities balance routes and work faster. It lets trucks work more hours each day. In Lexington, Kentucky, the city used this software to fix unfair workloads. Some drivers had to pick up only 600 carts. Others had to pick up as many as 1,600. After using the software, the city made the routes more fair. Drivers finished their work sooner. The city could also change routes three times faster than before. Garbage collection became easier and more dependable.

Route optimization lets cities save time and money. It helps trucks do more work and makes waste collection better.

Bin Compatibility

The kind of garbage bin changes how fast trucks can collect trash. Side loader trucks use an automated arm to grab standard wheeled bins. One operator can drive and control the arm from inside the cab. This works best in places where people use curbside bins. It means workers do not have to lift heavy trash. This lowers the chance of getting hurt.

Rear loader trucks can pick up many kinds of bins, even big or odd ones. They need more workers to load trash by hand. This takes longer at each stop and can cause more injuries. The table below compares side loader and rear loader trucks on important points:

Metric | Side Loader | Rear Loader |

|---|---|---|

Bin Compatibility Rate | 95+% with standardized wheeled bins (64–96 gallon) | Compatible with bulk and non-standard containers |

Stop Time per Bin | 15–25 seconds (automated arm) | Over 2 minutes (manual loading) |

Labor Required | 1 operator | 2–3 crew members |

Container Damage Rate | 2% | 15% |

Injury Rate | Reduced due to automation | Higher due to manual lifting |

Cost Effectiveness | 68% more cost-effective per ton in residential areas | Less cost-effective due to labor and time |

Side loaders work best with standard bins and in places with lots of homes. They pick up trash faster and need fewer workers. Rear loaders can pick up big or strange-shaped trash, but they need more time and people. Cities pick the right truck for the types of trash and bins they have. This helps make waste collection better and keeps things running well.

Crew and Safety

Labor Needs

How many workers a city needs depends on the truck type. Rear loader garbage trucks usually need more people to work. Most cities use two or three workers for each rear loader. Two workers stand at the back and put trash in the truck. One person drives and helps with the controls. This setup is good for picking up big or mixed trash. But it costs more because more people are needed.

Side loader garbage trucks use machines to help the crew. Many side loaders have robotic arms that grab garbage bins. One operator can drive and use the arm from inside the cab. This means fewer workers are needed. Some cities changed from three-person rear loader crews to one-person side loader teams. They saw lower labor costs and got more work done. Other cities went from two-person side loader crews to just one operator. This helped keep workers from quitting. Most rear loader garbage trucks still need 2–3 crew members. Side loader garbage trucks often need only one.

Rear loader garbage trucks: 2–3 crew members

Side loader garbage trucks: 1 operator

Cities using automated side loader garbage trucks can save money and pick up trash faster.

Safety Factors

Safety is very important in garbage collection. Rear loader garbage trucks need workers to stand at the back and lift heavy trash. This can cause injuries from lifting or from cars driving by. Workers can get hurt by sharp things, falling, or slipping. Side loader garbage trucks are safer because the operator stays inside the cab. The robotic arm lifts the bins, so workers do not touch the trash or go into the street.

Modern garbage trucks have safety features like backup cameras, warning lights, and emergency stop buttons. These features help stop accidents and keep everyone safe. Automated garbage trucks lower the chance of getting hurt and make the job safer. Cities using side loader garbage trucks have fewer accidents and less time lost to injuries.

Automated garbage trucks help keep workers safe and lower the dangers of picking up trash on busy city streets.

Urban Maneuverability

Tight Streets

Rear loader and side loader trucks are important in cities with narrow streets. Rear loader trucks are small and can turn easily. They fit into alleys and dead ends. Their size and weight help drivers in crowded places. Many rear loaders have cameras, mirrors, and sensors. These tools help drivers see better and avoid crashes.

Rear loaders use machines to load trash. This keeps workers away from the back of the truck. It lowers the chance of accidents in small spaces. Rear loaders pick up trash from many kinds of bins. They can work on different routes. This helps keep streets clean, even in hard places.

Side loader trucks also work well in tight streets. Their arms grab bins from the curb. The truck does not need to park behind each bin. This lets side loaders move easily through narrow roads. They collect trash fast and do not block the street for long.

Tip: Both rear loader and side loader trucks help cities pick up trash in tight spaces. This keeps neighborhoods cleaner.

Traffic Impact

Sanitation trucks can change city traffic when picking up trash. Side loader trucks use arms to grab bins from the side. This needs less space and keeps the truck near the curb. Side loaders do not block traffic as much. They pick up many bins in one trip. This means fewer stops and starts. Cars and buses can move around the truck more easily.

Rear loader trucks need space behind them to load trash. In busy streets, this can block a lane and slow traffic. More workers around the truck can cause more accidents or delays. But rear loaders are good for big trash and tight spots.

Side loaders help traffic move and make streets safer.

Rear loaders may slow traffic but can handle more types of trash.

Cities pick the truck that works best for their streets and traffic.

Cost Factors

Purchase and Operation

Cities look at costs before buying sanitation trucks. Rear loader trucks cost less to buy. This helps cities with small budgets. Side loader trucks cost more at first. Automated side loaders save money over time. The table below shows cost differences:

Cost/Aspect | Side Loader Trucks (Automated) | Rear Loader Trucks (Manual) |

|---|---|---|

Initial Purchase Cost | $363,300 per truck | Lower initial cost (varies) |

Crew Size Required | 1 operator | 2–3 workers |

Operational Cost Impact | Lower due to labor savings | Higher due to more workers |

Maintenance & Repair Costs | Lower (new trucks) | Higher (older trucks) |

Side loaders need only one operator. This lowers labor costs. Rear loaders need two or three workers. This raises costs for pay and insurance. Automated side loaders work faster and use less fuel. Many cities save money in the long run with side loaders. The first cost is higher, but savings come later.

Tip: Cities that pick side loaders often pay less for workers and get jobs done faster.

Maintenance

Maintenance affects how much trucks cost over time. Automated side loaders have more parts and new technology. They need regular care to keep working well. Workers grease the arms every day and check the trucks often. Side loaders follow strict schedules for care. Repairs can cost more because the systems are complex.

Rear loader trucks are simpler. They need less care and are easier to fix. Manual rear loaders cost less to maintain. Older rear loaders may break down more. Cities must plan for higher repair costs with old trucks. New ideas like modular hydraulic systems and powder-coated bodies help both types need less care.

Automated side loaders are safer and work better. Cities must plan for higher care costs. Rear loaders cost less to buy and fix. But they may cost more for workers and safety over time.

Environmental Impact

Emissions

Municipal sanitation vehicles make different kinds of emissions when they collect trash. Both rear loader and side loader trucks give off nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO). These emissions go up when trucks are heavier. Newer trucks have special controls that help lower pollution.

The table below shows the average emissions for side loader refuse trucks from real-world tests:

Emission Metric | Side-loader RT Emissions (2002-2006 models) | Notes |

|---|---|---|

NOx Emissions | Higher during trash collection than highway driving | |

PM Emissions | 1.1 to 2.7 g/mile | Particulate matter during collection |

CO Emissions | 8.3 to 38.2 g/mile | Carbon monoxide during collection |

Emission Reduction | Up to 80% NOx, 95% PM reduction with SCR/DPF | Newer trucks with advanced controls |

Fuel Economy | 1 to 3 miles per gallon | Average for rear- and side-loader trucks |

Effect of Vehicle Weight | Emissions rise by 15-19% for CO2 and NOx | Heavier trucks produce more pollution |

CJQC’s sanitation vehicles use hybrid systems and emission controls to cut down NOx and PM. These trucks help cities reach clean air goals and use less fuel.

Trucks with special emission controls keep the air cleaner and help people stay healthy.

Water and Energy Use

Sanitation vehicles also use water and energy. Many trucks spray water to clean streets and stop dust. Older trucks may waste water or burn more fuel. CJQC’s AquaSmart™ system helps cities save water. This system changes water flow based on what is needed right then. It uses rainwater when it can and changes how much water comes out depending on wind and ground shape.

Hybrid trucks from CJQC use both diesel and electric power. They save energy with brakes that make power and solar panels. These features help lower fuel costs and cut greenhouse gases. Cities like Los Angeles have saved lots of water and used less energy with CJQC’s vehicles.

Key benefits of advanced water and energy systems:

Use less water

Burn less fuel

Make fewer greenhouse gases

Save money on running trucks

Using smart water and energy systems in sanitation vehicles helps cities protect nature and work better.

Real-World Case Studies

CJQC Success Stories

CJQC helps cities pick up trash better and protect nature. Singapore’s National Environment Agency got 28 hybrid trucks. These trucks used 42% less diesel fuel. Crews finished 17% more routes each day. The trucks were quiet and did not break noise rules. This made neighborhoods more peaceful. Los Angeles used AquaSmart sprinklers with smart rain prediction. The city used 39% less water for city work. Water bills went down by $2.7 million each year. Los Angeles won the 2024 Green Innovation Award for these changes.

CJQC’s AquaSmart system checks water flow all the time. It moves nozzles to match wind and ground shape. The system also uses rainwater to save more water. EcoPower Hybrid Systems use both diesel and electric power. Trucks save energy when braking and can use solar panels. These things help cut fuel use, pollution, and noise. Cities spend less money and help the planet.

Vehicle Model | Water Capacity | Coverage per Cycle | Noise Level (dB) | Daily Operational Cost | CO2 Emission Reduction |

|---|---|---|---|---|---|

Standard Model | 8,000L | 15 km | 78 | $185 | 12% |

EcoSmart Model | 8,000L | 22 km | 71 | $128 | 32% |

Hybrid Model (HOWO) | 12,000L | 28 km | 68 | $95 | 45% |

Cities that use CJQC trucks pay less and help the environment.

Global Examples

Many cities use rear loader and side loader trucks to keep streets clean. New York City’s Department of Sanitation started a test with automated side loader trucks. These trucks pick up trash from big apartment buildings. The city wants to try shared bins and single carts. This plan should make streets cleaner and stop rats. The test starts in Manhattan Community Board 9 in spring 2025.

Other cities have good results too:

City / Operator | Vehicle Type | Implementation Details | Outcome / Impact |

|---|---|---|---|

Detroit & Battle Creek, MI (Waste Management) | Rear Loader | Fixed up an old 1960s rear loader truck for shows and events. | Older adults liked seeing a truck they remembered. |

East Lansing, MI | Side Loader | Uses side loader trucks for homes that join the curbside program; trucks have clear signs. | Gained about 2,500 new customers in less than a year; now serves 6,000 homes. |

Cities everywhere use new tools and smart ideas to make trash pickup safer and faster.

Municipal Waste Management Insights

Choosing the Right Vehicle

Cities have many choices when picking sanitation vehicles. Leaders must think about what their city needs. They look at different things to find the best fit.

Versatility and Use Cases: Rear loaders are good for cleaning up after events. They help with recycling and work in the countryside. These trucks can handle many kinds of roads and trash. Side loaders are better for busy city areas and business places. Their machines make trash pickup faster and safer.

Vehicle Types and Features: Rear loaders come in many sizes and types. Some are small, some are big, and some use machines. Side loaders often have arms that grab bins and smart controls. Cities should think about how the truck packs trash, uses machines, and if it is easy for workers to use.

Labor and Safety: Rear loaders need more people to work. Side loaders use machines, so fewer workers are needed. Safety tools like cameras and warning systems help keep everyone safe.

Environmental Impact: Electric and hybrid trucks help lower pollution and noise. New tools like GPS and route planning help cities be greener and work better.

Budget and Maintenance: Buying new or special trucks can cost a lot at first. Trucks need care like checking machines and engines. Small cities may have trouble paying for new trucks or teaching workers.

Regulatory Compliance: Cities must follow rules for pollution, safety, and truck types. These rules decide which trucks can be used and how they work.

The table below shows how rear loader and side loader trucks are different:

Feature/Aspect | Rear Loader Garbage Trucks | Side Loader Garbage Trucks |

|---|---|---|

Operation | Manual or mechanical rear loading | Automated side-mounted arm |

Labor Requirement | More manual labor | Reduced labor, driver stays in cab |

Maneuverability | Good for narrow streets | Best for dense urban areas |

Cost | Lower upfront and operational | Higher upfront, lower labor |

Efficiency | Less efficient, more manual work | High efficiency, automated |

Tip: Cities should pick trucks that fit their roads, trash, and how many people live there.

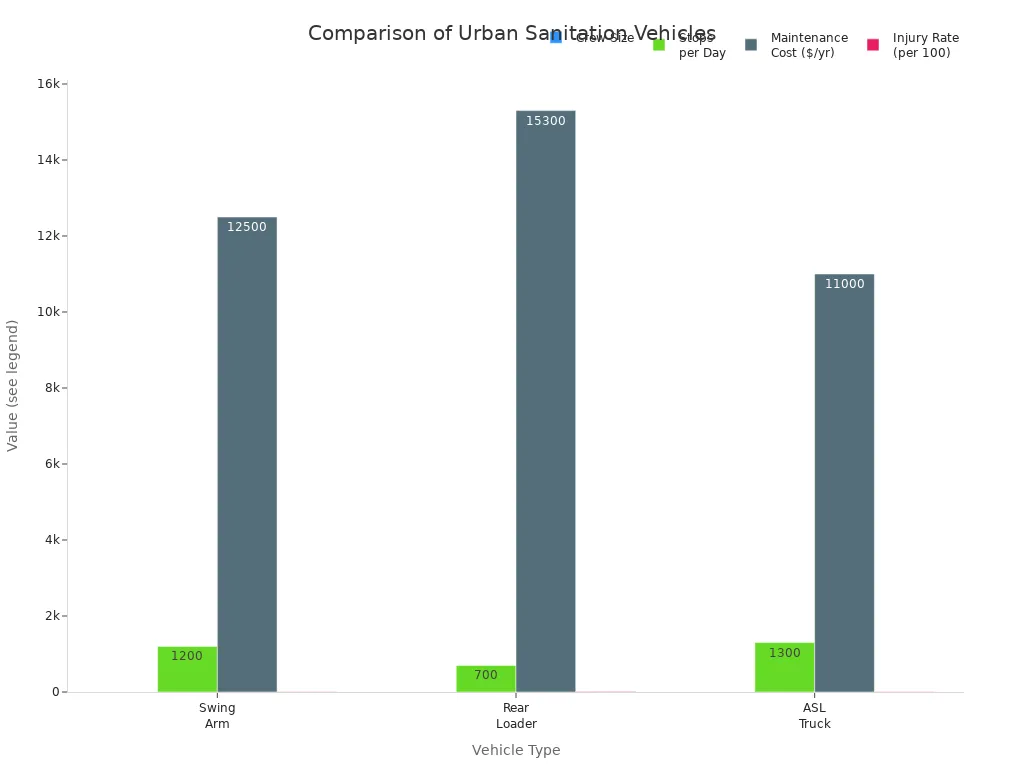

Recent research shows swing arm trucks need fewer workers. They can make more stops each day. They also cost less to keep working than rear loaders or automated side loaders. Cities like Toronto and Singapore finished routes faster and had fewer accidents. CJQC’s new trucks use hybrid engines and smart water systems. These features help cities save money and protect nature.

Feature | Swing Arm Trucks | Rear Loader Trucks | Automated Side Loader Trucks |

|---|---|---|---|

Crew Size | 1–2 | 3 | 1 |

Stops per Day | Up to 1,200 | Around 700 | 1,200–1,400 |

Maintenance Cost | $12,500/year | $15,300/year | $11,000/year |

Safety (Injury Rate) | 8.3/100 | 12.1/100 | 4.1/100 |

Cities should pick trucks that fit their roads and bins. Using smart tech and hybrid engines makes trash pickup safer and easier.

FAQ

What is the main difference between rear loader and side loader sanitation vehicles?

Rear loader trucks pick up trash from the back. Side loader trucks use an arm to grab bins from the side. Side loaders usually need just one person to run them. Rear loaders can take bigger and heavier trash.

How do automated systems improve waste collection?

Automated systems have robotic arms and sensors. These tools help trucks grab bins faster and more safely. They help workers get hurt less and save time on each route.

Are hybrid sanitation vehicles better for the environment?

Hybrid vehicles use diesel and electric power together. They use less fuel and make less pollution. Cities with hybrids have cleaner air and spend less money.

Can CJQC vehicles work in cities with narrow streets?

CJQC makes trucks for small city streets. Their trucks have short wheelbases and special steering. These things help drivers turn and park in crowded places.

How do cities save money with advanced sanitation vehicles?

Cities save money by needing fewer workers and using less fuel. Smart systems like AquaSmart™ help control water use. Hybrid engines help lower energy bills. These features help cities spend less each day.